Our achievements in the Pharmaceutical industry

API workshop with conical dryer

Clean rooms, Air treatment, CIP, Utilities, Drying, Packaging, Building

Conical dryer (clean area / technical area)

Clean rooms, Air treatment, CIP, Utilities, Drying, Packaging, Building

Packaging

Clean rooms, Air treatment, CIP, Utilities, Drying, Packaging, Building

Utilities

Clean rooms, Air treatment, CIP, Utilities, Drying, Packaging, Building

Building's 3D view

Biotechnological-pharmaceutical unit

Fermentation, Filtration, Centrifugation, Clean rooms

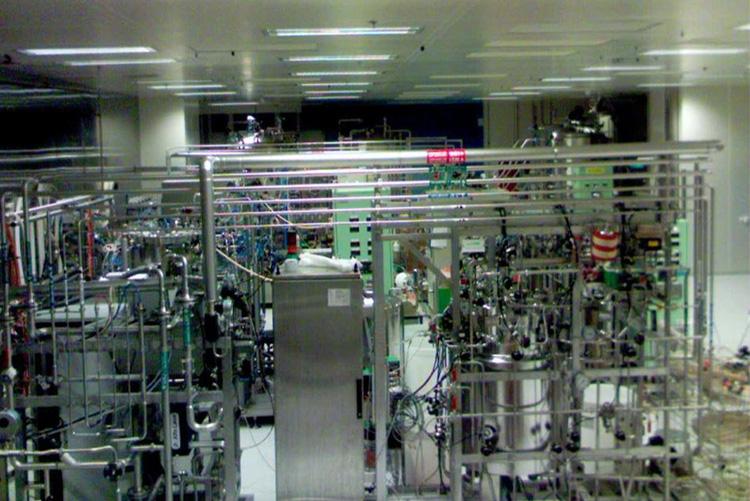

Fermentation workshop

Fermentation, Filtration, Centrifugation, Clean rooms

Fermentation / Filtration

Fermentation, Filtration, Centrifugation, Clean rooms

Clean rooms

Insulin production unit

Press filter, Ultrafiltration, Chromatography, HPLC, HVAC classe D and C

Chromatography

Press filter, Ultrafiltration, Chromatography, HPLC, HVAC classe D and C

Purification workshop

Blood plasma fractionation production unit

Centrifugation, Precipitation, Filtration, Chromatography, Freeze drying

Controlled environment

Centrifugation, Precipitation, Filtration, Chromatography, Freeze drying

Isolators

Active principles production unit

Extraction, Separation, Sieving, Freeze drying

Extraction –Clean room

Extraction, Separation, Sieving, Freeze drying

Freeze drying

Extraction, Separation, Sieving, Freeze drying

Building manufacturing

Historically, we have worked in the laboratory and pharmaceutical industry, particularly in human blood plasma fractionation, extraction, separation, production units, both sieving, freeze drying in France and abroad. This experience has enabled us to position in this business. To ensure compliance with regulations, this specific business requires a rigorous and controlled projects organization, with the different qualification step throughout the studies, construction and commissioning, to allow the user to validate its production as well.